文章来源:http://www.trcables.com/ 作者:上海嗨润 发布时间::2018-01-18 14:00 浏览次数:次

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems,

airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

STANDARDS

Basic design adapted to IEC 60502-1; BS 5467

FIRE PERFORMANCE

|

Flame Retardance (Single Vertical |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE |

|

Reduced Fire Propagation |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Note: Asterisk ** denotes that the standard compliance is optional, depending on the oxygen index of the PVC

compound and the cable design.

VOLTAGE RATING

600/1000V

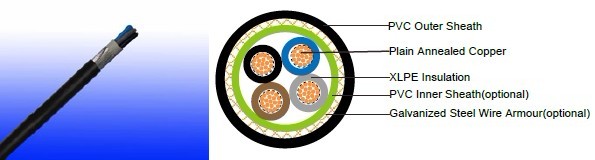

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

Insulation: Extruded cross-linked XLPE compound.

Inner Sheath(optional): PVC Compound

Armouring(optional): Galvanized Steel Wire

Outer Sheath: Thermoplastic PVC compound. UV resistance, hydrocarbon resistance, oil resistance,

anti rodent and anti termite properties can be offered as option. Compliance to fire performance

standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the

PVC compound and the overall cable design. LSPVC can also be provided upon request.

COLOUR CODE

Insulation Colour as per BS7671

|

|

With Earth Conductor |

Without Earth Conductor |

|

2Cores |

- |

Brown, Blue |

|

3Cores |

Yellow/Green, Brown, Blue |

Brown, Gray, Black |

|

4Cores |

Yellow/Green, Brown, Gray, Black |

Brown, Gray, Black, Blue |

|

5Cores |

Yellow/Green, Brown, Gray, Black, Blue |

Brown, Gray, Black, Blue, Black |

|

Above 5 Cores |

Yellow/Green, Black Numbered |

Black Numbered |

Sheath Colour: Black (other colors upon request)

Physical AND THERMAL PROPERTIES

Temperature range during operation: Max.90°C for XLPE

250°C in short-circuit for 5secs max.

Minimum bending radius: 8 x Overall Diameter (unarmoured cable)

10 x Overall Diameter (armoured cable)

CONSTRUCTION PARAMETERS

| Conductor | FGD400 1RV-R | FGD400 1RVMV-R | ||||||

|

No. of Core |

No./ Nominal Diameter of |

Nominal Insulation Thickness |

Unarmoured | Armoured | ||||

|

Nominal Overall Diameter |

Approx. Weight |

Diameter Over Inner Sheath |

Armour Wire Diameter |

Nominal Overall Diameter |

Approx. Weight |

|||

| mm2 | No./mm | mm | mm | mm | mm | mm | mm | kg/km |

| 2Cores | ||||||||

|

2G1.5 |

7/0.53 |

0.7 |

10.0 |

126 |

8.5 |

0.9 |

13.9 |

350 |

|

2G2.5 |

7/0.67 |

0.7 |

10.8 |

158 |

9.3 |

0.9 |

14.7 |

400 |

|

2G4 |

7/0.85 |

0.7 |

11.9 |

205 |

10.4 |

0.9 |

15.8 |

475 |

|

2G6 |

7/1.04 |

0.7 |

13.0 |

264 |

11.5 |

0.9 |

16.9 |

560 |

|

2G10 |

7/1.35 |

0.7 |

14.9 |

378 |

13.4 |

1.25 |

19.5 |

810 |

|

2G16 |

7/1.70 |

0.7 |

17.0 |

534 |

15.5 |

1.25 |

21.6 |

980 |

|

2G25 |

7/2.14 |

0.9 |

20.4 |

650 |

18.9 |

1.6 |

25.7 |

1410 |

|

2G35 |

7/2.52 |

0.9 |

22.7 |

880 |

21.2 |

1.6 |

28.0 |

1930 |

| 3Cores | ||||||||

|

3G1.5 |

7/0.53 |

0.7 |

10.5 |

145 |

9.0 |

0.9 |

14.4 |

390 |

|

3G2.5 |

7/0.67 |

0.7 |

11.4 |

185 |

9.9 |

0.9 |

15.3 |

450 |

|

3G4 |

7/0.85 |

0.7 |

12.5 |

247 |

11.0 |

0.9 |

16.4 |

540 |

|

3G6 |

7/1.04 |

0.7 |

13.8 |

323 |

11.6 |

1.25 |

17.7 |

745 |

|

3G10 |

7/1.35 |

0.7 |

15.8 |

474 |

14.3 |

1.25 |

20.4 |

950 |

|

3G16 |

7/1.70 |

0.7 |

18.0 |

682 |

16.5 |

1.25 |

23.0 |

1250 |

|

3G25 |

7/2.14 |

0.9 |

21.7 |

910 |

20.2 |

1.6 |

27.0 |

1840 |

|

3G35 |

7/2.52 |

0.9 |

24.0 |

1180 |

22.4 |

1.6 |

29.2 |

2050 |

|

3G50 |

19/1.78 |

1.0 |

25.5 |

1600 |

24.2 |

1.6 |

31.2 |

2590 |

|

3G70 |

19/2.14 |

1.1 |

29.0 |

2240 |

28.2 |

2.0 |

36.2 |

3560 |

|

3G95 |

19/2.52 |

1.1 |

33.5 |

3050 |

31.7 |

2.0 |

40.1 |

4590 |

|

3G120 |

37/2.03 |

1.2 |

37.5 |

3800 |

36.0 |

2.0 |

44.6 |

5810 |

|

3G150 |

37/2.25 |

1.4 |

40.5 |

4640 |

39.5 |

2.5 |

49.5 |

6920 |

|

3G185 |

37/2.52 |

1.6 |

45.0 |

5870 |

43.3 |

2.5 |

53.5 |

8340 |

|

3G240 |

61/2.25 |

1.7 |

50.5 |

7670 |

48.4 |

2.5 |

59.0 |

10450 |

|

3G300 |

61/2.52 |

1.8 |

57.0 |

9460 |

54.4 |

2.5 |

65.4 |

12700 |

|

3G400 |

61/2.85 |

2.0 |

63.0 |

11945 |

57.8 |

2.5 |

70.0 |

15326 |

|

3Cores+1Core Earth Conductor |

||||||||

|

3G10+6 |

7/1.35 |

0.7 |

16.5 |

543 |

17.6 |

1.25 |

20.1 |

1042 |

|

3G16+10 |

7/1.70 |

0.7 |

18.85 |

793 |

20.6 |

1.25 |

22.5 |

1567 |

|

3G25+10 |

7/2.14 |

0.9 |

22.1 |

1021 |

26.3 |

1.25 |

23.6 |

2091 |

|

3G25+16 |

7/2.14 |

0.9 |

23.0 |

1070 |

26.6 |

1.25 |

25.8 |

2150 |

|

3G35+16 |

19/1.53 |

0.9 |

24.3 |

1349 |

26.8 |

1.6 |

27.7 |

2390 |

|

3G35+25 |

19/1.53 |

0.9 |

25.2 |

1470 |

27.2 |

1.6 |

28.6 |

2505 |

|

3G50+16 |

19/1.78 |

1 |

26.1 |

1769 |

28.5 |

1.6 |

29.8 |

2916 |

|

3G50+25 |

19/1.78 |

1 |

27.3 |

1890 |

29.2 |

1.6 |

31.3 |

3107 |

|

3G50+35 |

19/1.78 |

1 |

27.8 |

1995 |

30.0 |

1.6 |

32.0 |

3175 |

|

3G70+25 |

19/2.14 |

1.1 |

30.2 |

2530 |

34.0 |

2.0 |

35.0 |

3203 |

|

3G70+35 |

19/2.14 |

1.1 |

30.9 |

2660 |

34.5 |

2.0 |

35.9 |

4067 |

|

3G70+50 |

19/2.14 |

1.1 |

31.5 |

2840 |

35 |

2.0 |

36.8 |

4310 |

|

3G95+16 |

19/2.52 |

1.1 |

34.6 |

3240 |

36.3 |

2.0 |

38.0 |

4856 |

|

3G95+25 |

19/2.52 |

1.1 |

35.1 |

3340 |

36.7 |

2.0 |

39.3 |

5047 |

|

3G95+35 |

19/2.52 |

1.1 |

36.0 |

3470 |

37.2 |

2.0 |

40.2 |

5115 |

|

3G95+50 |

19/2.52 |

1.1 |

36.8 |

3650 |

37.6 |

2.0 |

41.4 |

5289 |

|

3G120+35 |

37/2.03 |

1.2 |

38.2 |

3920 |

39.4 |

2.5 |

44.0 |

6160 |

|

3G120+50 |

37/2.03 |

1.2 |

39.1 |

4400 |

39.9 |

2.5 |

44.9 |

6473 |

|

3G120+70 |

37/2.03 |

1.2 |

40.0 |

4610 |

40.3 |

2.5 |

45.6 |

6793 |

|

3G120+95 |

37/2.03 |

1.2 |

41.2 |

4820 |

41.2 |

2.5 |

46.8 |

7120 |

|

3G150+50 |

37/2.25 |

1.4 |

41.5 |

5240 |

45.0 |

2.5 |

49.7 |

7549 |

|

3G150+50 |

37/2.25 |

1.4 |

42.3 |

5450 |

45.2 |

2.5 |

49.8 |

7565 |

|

3G150+95 |

37/2.25 |

1.4 |

43.6 |

5660 |

45.5 |

2.5 |

50.8 |

8196 |

|

3G150+120 |

37/2.25 |

1.4 |

44.8 |

6240 |

46.0 |

2.5 |

51.8 |

8590 |

|

3G185+70 |

37/2.52 |

1.6 |

46.0 |

6470 |

50.4 |

2.5 |

54.0 |

8950 |

|

3G185+95 |

37/2.52 |

1.6 |

47.5 |

6680 |

50.6 |

2.5 |

54.7 |

9573 |

|

3G185+120 |

37/2.52 |

1.6 |

47.9 |

6990 |

51.0 |

2.5 |

55.8 |

9968 |

|

3G185+150 |

37/2.52 |

1.6 |

48.5 |

7395 |

51.6 |

2.5 |

56.6 |

1023 |

|

3G240+70 |

61/2.25 |

1.7 |

49.2 |

7580 |

57.0 |

2.5 |

56.0 |

11294 |

|

3G240+95 |

61/2.25 |

1.7 |

52.3 |

8480 |

58.0 |

2.5 |

57.9 |

11620 |

|

3G240+120 |

61/2.25 |

1.7 |

53.4 |

8690 |

59.0 |

2.5 |

61.0 |

12015 |

|

3G240+150 |

61/2.25 |

1.7 |

54.9 |

9095 |

60.0 |

2.5 |

62.2 |

12373 |

|

3G300+95 |

61/2.52 |

1.8 |

55.6 |

9380 |

63 |

2.5 |

64.7 |

13803 |

|

3G300+120 |

61/2.52 |

1.8 |

58.1 |

10480 |

64.2 |

2.5 |

65.9 |

14197 |

|

3G300+150 |

61/2.52 |

1.8 |

57.3 |

11170 |

65.7 |

2.5 |

66.8 |

14556 |

|

3G300+185 |

61/2.52 |

1.8 |

58.7 |

11480 |

66.4 |

2.5 |

68.1 |

15015 |

|

3G300+240 |

61/2.52 |

1.8 |

62.4 |

11290 |

67 |

2.5 |

69.4 |

15697 |

|

4Cores |

||||||||

|

4G1.5 |

7/0.53 |

0.7 |

11.3 |

169 |

10.0 |

0.9 |

15.4 |

430 |

|

4G2.5 |

7/0.67 |

0.7 |

12.3 |

220 |

10.8 |

0.9 |

16.2 |

505 |

|

4G4 |

7/0.85 |

0.7 |

13.6 |

297 |

12.1 |

0.9 |

17.5 |

710 |

|

4G6 |

7/1.04 |

0.7 |

15.0 |

392 |

13.5 |

1.25 |

19.6 |

855 |

|

4G10 |

7/1.35 |

0.7 |

17.2 |

585 |

15.7 |

1.25 |

21.8 |

1120 |

|

4G16 |

7/1.70 |

0.7 |

19.7 |

851 |

18.2 |

1.6 |

25.0 |

1600 |